Introduction

Pural SB powder and Molecular Zeolite technology in hydrocracking catalyst applications within the petroleum refining segment. Under the deal, both companies will further develop, manufacture, and market hydrocracking catalysts for the refining industry.

Refining catalysts, made from mesostructured zeolites, show higher selectivity and reduce the production of heavy bottoms and coke compared to conventional methods. This allows refiners to increase fuel production by processing heavier crudes.

Polymerization catalysts play a catalytic role in the formation of high molecular weight polymers from low molecular weight monomers through the chain growth process. The common characteristic of polymerization catalysts is the use of transition metals (iron, cobalt, nickel, etc.) as the active center of the catalyst, in which the catalytic performance was compared through the difference of high olefins polymerization reaction under conditions of medium pressure and low pressure. Most transition metals have unpaired single electrons in the d orbital, which is an important reason for their catalytic effect.

Types of Polymerization Catalysts

- Olefin Polymerization Catalysts

Ziegler-Natta (Z-N) catalysts are composite catalysts for olefin polymerization, which is the beginning of the development of composite catalysts and promotes the rapid development of directional polymerization and selective oligomerization. Z-N catalysts are mainly used in the conventional polymerization of alpha-olefins, and are also commonly used in the conventional polymerization of diolefins and cyclic olefins. Z-N catalysts are widely used in automotive, chemical, food and other industries due to their high activity, low cost, good stability, and suitability for large-scale continuous production.

- Metal Catalysts

Compared with traditional Ziegler-Natta catalysts, metal catalysts have more precise controllability, which mainly depends on the structure of metal ligands. For example, metallocene catalysts are pentadentate complexes formed by cyclopentadiene or its derivatives (indene, fluorene) and IVB transition metal atoms titanium and zirconium. Metallocene catalysts can effectively modulate the chain extension reaction of olefin molecules, resulting in polymers with high structural regularity.

- Organometallic Complex Catalysts

Organometallic complex catalysts are defined as organometallic complexes with oxygen, nitrogen, phosphorus and sulfur as coordination atoms and transition metal elements as metal centers. This new generation of catalyst not only retains the advantages of high activity of metal catalysts, easy introduction of a variety of comonomers, and controllable polymer structure, but also has the advantages of diverse structures, good stability, and low production costs. Catalysts can be divided into monodentate ligands and chelating polydentate ligands according to the number of ligands they contain, which have different catalytic effects in polymerization reactions.

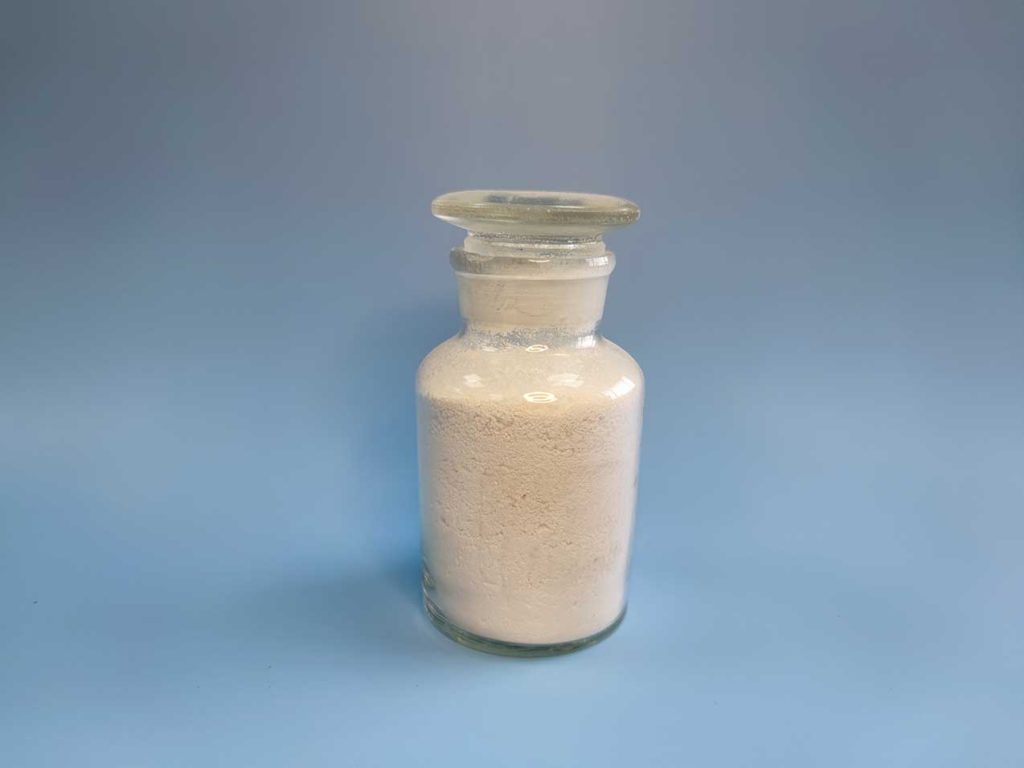

Pural SB Powder was used in most zeolite catalysts, and supply is more and more shortage in the market. International oil and gas cost were increased more, so it was influenced to most European manufacturers, and their facotries have to stop production in order to follow local government policy. It made in Germany, USA and China. Like Sasol factories of Pural SB Powder control 65% market based high level technology. Today, Most sales contract have to delay to delivery on 2023, because of European gas supply shortage. Local government promise all family usage in winter. It is not a good news to all manufacturers.

Chemical Composition: AlOOH x H2O

Crystal Structure: Boehmite

Chemical Data of Pural SB Powder

| Al2O3% | 70 min. | |

| C% | 0.5 max. | |

| SiO2% | 0.015 max. | |

| Fe2O3% | 0.015 max. | |

| Na2O% | 0.005 max. | |

| Physical Properties | ||

| Loose Bulk Density | g/l | 680 – 800 |

| Crystallite Size | nm | 4.5-6.0 |

| Surface Area (3h/550°C) | m²/g | 230 min. |

| Pore Volume | ml/g | 0.5 min. |

| Particle Size Distribution | ||

| < 25 µm | % | 40.0 max. |

| < 45 µm | % | 55.0 max. |

| > 90 µm | % | 18.0 max. |

Reference

- Polymerization Catalysts Market to See 5.4% Annual Growth Through 2023

- In Addition, natural zeolite has the similar function as synthetic zeolite. please reference this link.

- Catalysts additive and Synthesis Production of Biodiesel from Castor Oil

- Multiscale Dynamic Crosstalk Technology of Zeolite Catalysts in Methanol to Olefins Reaction

- Best Catalysts: Application of Pural SB Powder (Sasol Boehmite)